INJECTABLES

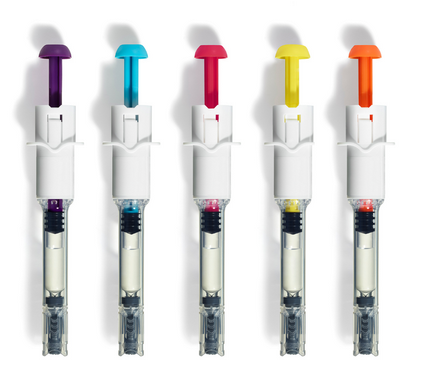

Pre-filled syringes

Pre-filled Syringes with luer-Lock or needle tip (8,15 or 10,85 outside diameter)

Fill volume: 0,3 to 2 ml

Mixing, compounding, sterilisation, visual inspection and packaging:

- Solutions or ready-to-fill bulk

- Aseptic filtration and/or autoclaving

- Fully automated 100% visual inspection

- Device assembly

- In-line fully automated blister-packing, cartonning, leaflet, serialisation, shipper, aggregation palletisation

Site: Aspen Notre Dame de Bondeville S.A.S (France)

Capacity per year: 280 million

Vials

Glass ampoules and cartridges

Blow Fill and Seal (BFS)

Form Fill and Seal (infusion bags)

Form Fill and Seal Semi-rigid infusion bags

Fill volume: 100 to 200 ml (smaller or larger size upon request)

Mixing, compounding, sterilisation, visual inspection and packaging:

- Solutions

- Aseptic filtration and autoclaving in blister-packs

- Fully automated and in-line 100% leak detection and visual inspection

- In-line fully automated cartonning, leaflet, serialisation and/or aggregation

Site: Aspen Notre Dame de Bondeville S.A.S (France)

Capacity per year: 4 million

NON-INJECTABLES

Blow Fill and Seal (nebules)

BFS nebules for inhalation PE (PolyEthylene)

Fill volume: 2.5 ml

Mixing, compounding, sterilisation, visual inspection and packaging:

- Solution

- Fully automated in-line 100% leak detection

- Aluminum pouching

- In-line fully automated cartonning, leaflet, serialisation

Site: Aspen Bad Oldesloe GmbH (Germany)

Capacity per year: 11 million

Gels (topical) Eye-drops